【ベストコレクション】 hepa filter classification 904625-Original miele hepa filter classification 13

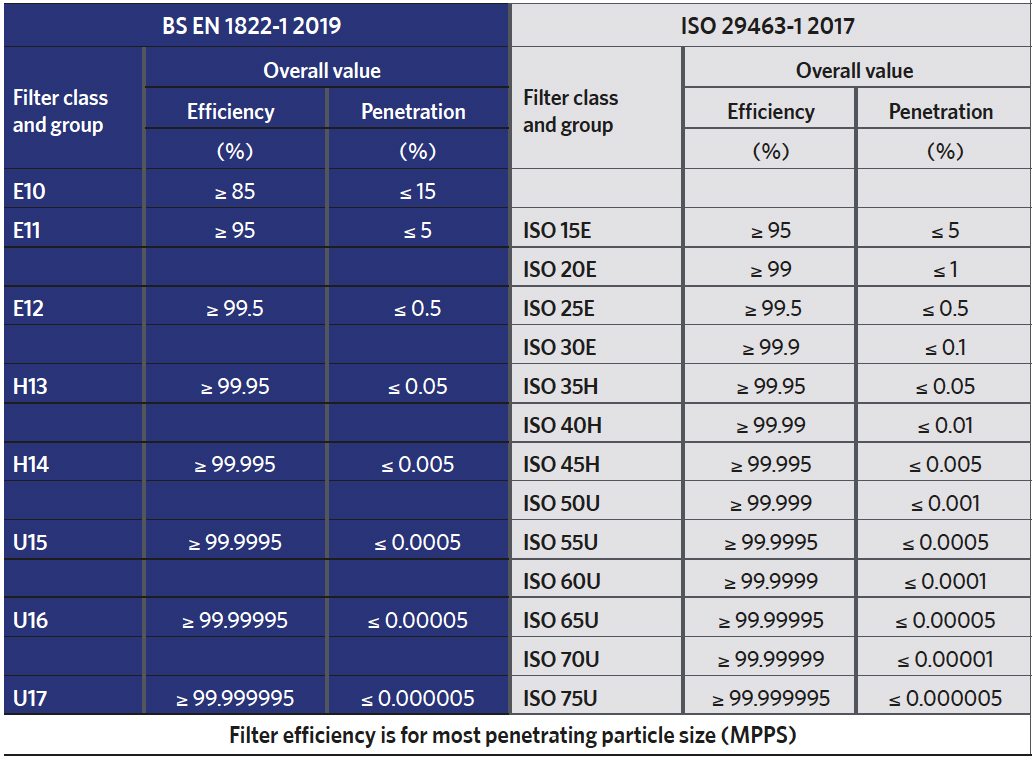

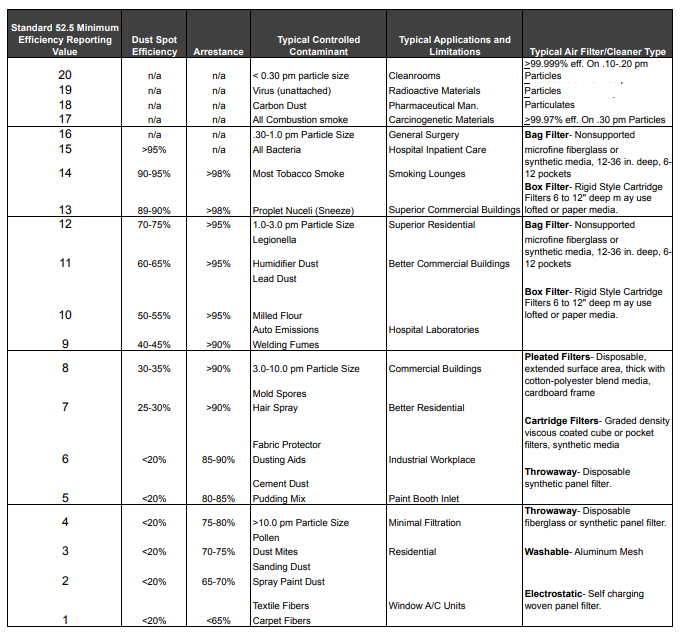

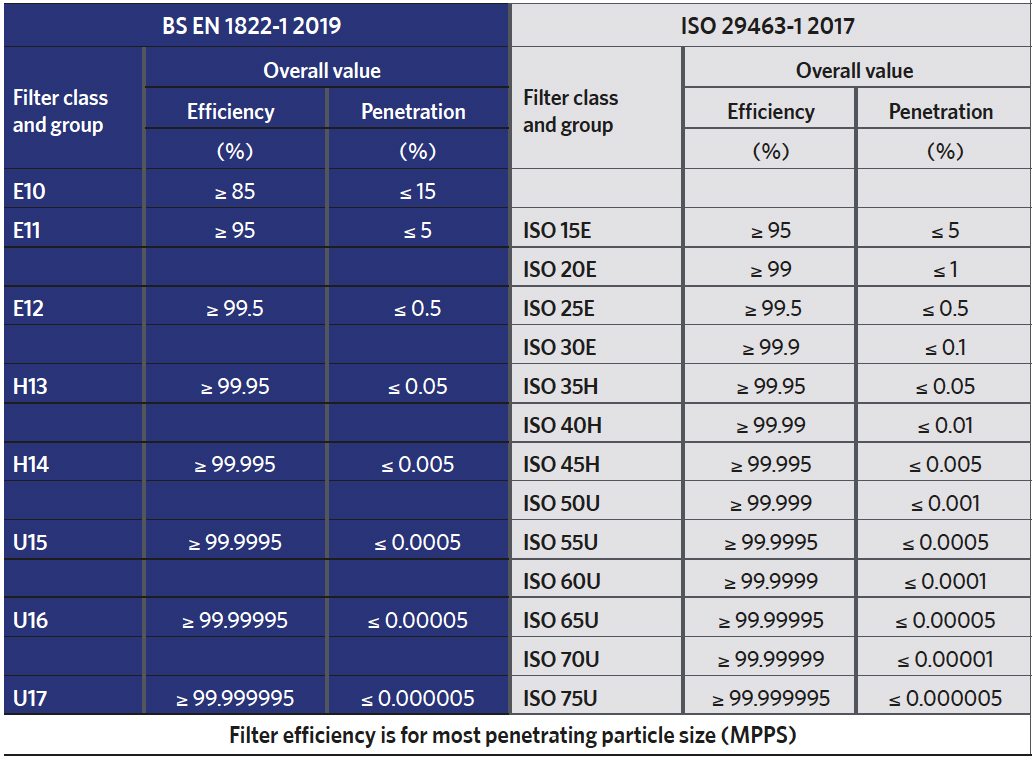

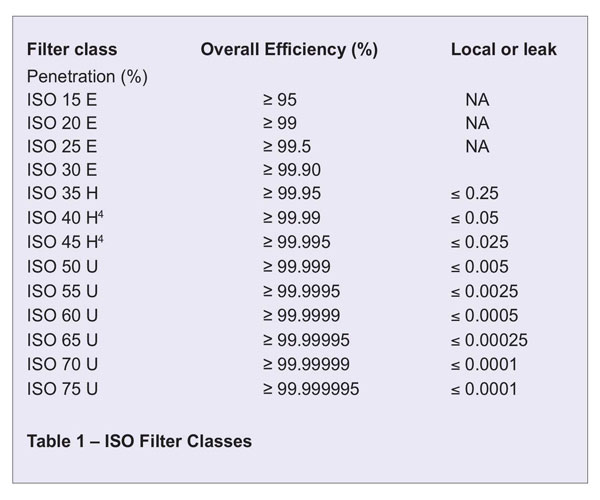

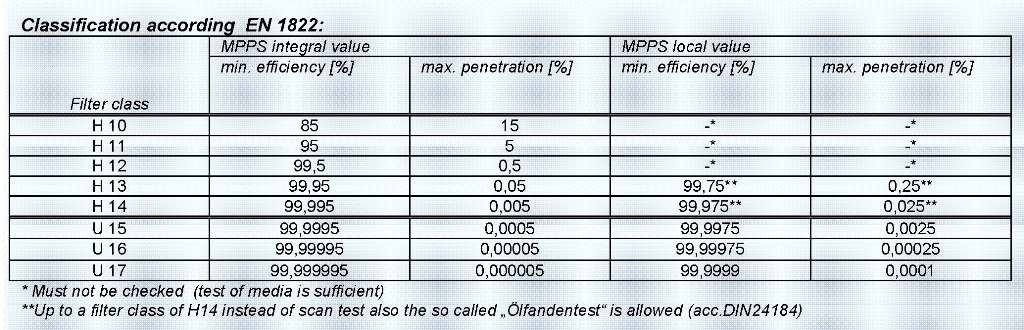

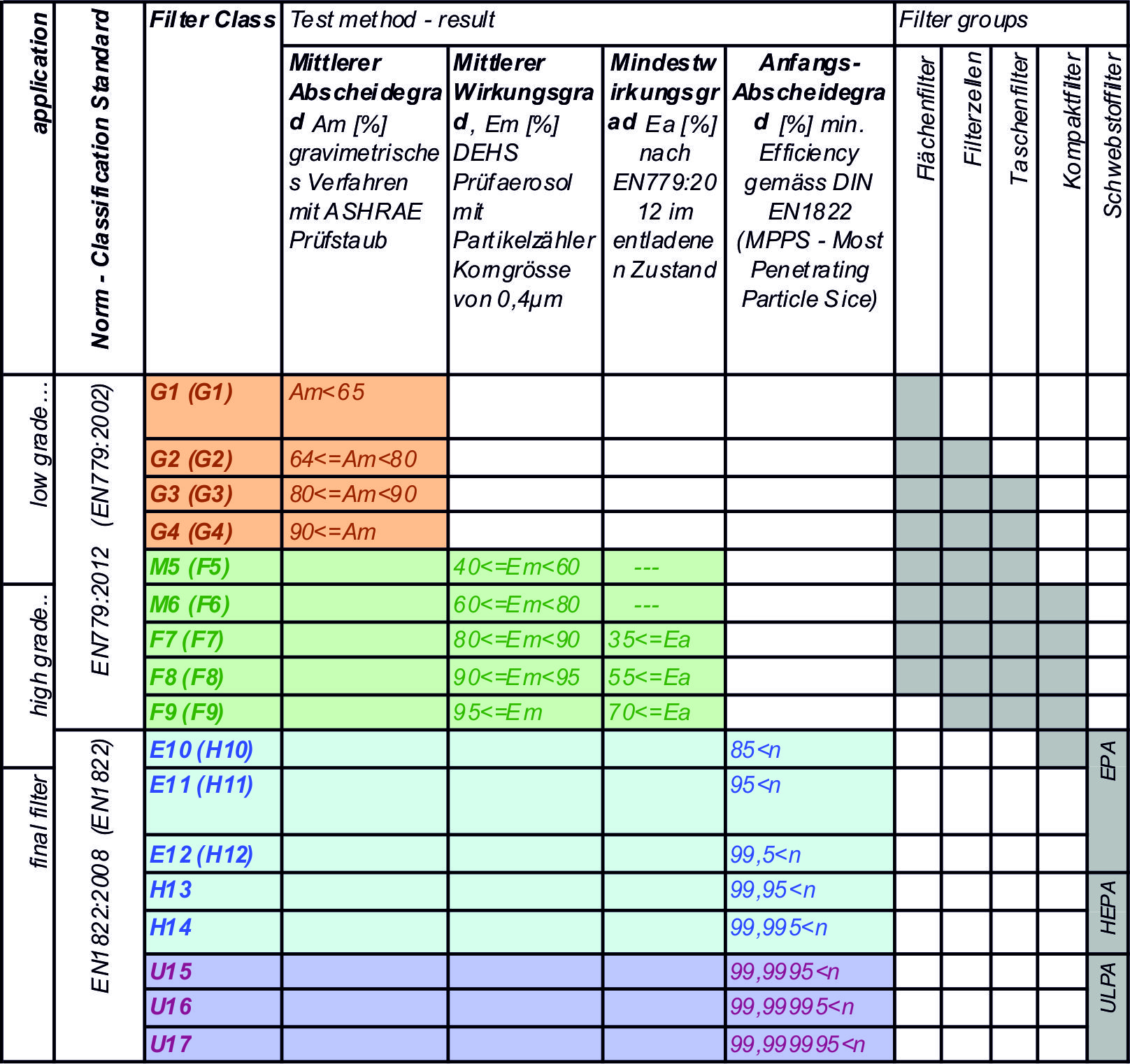

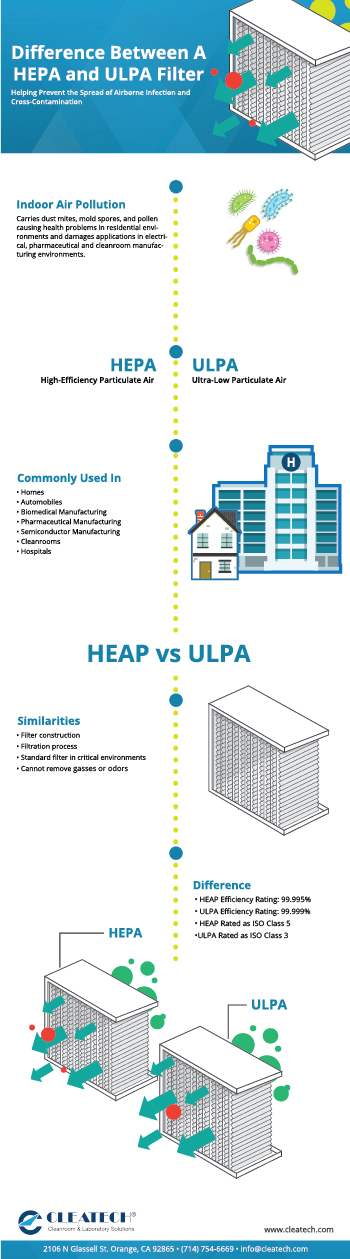

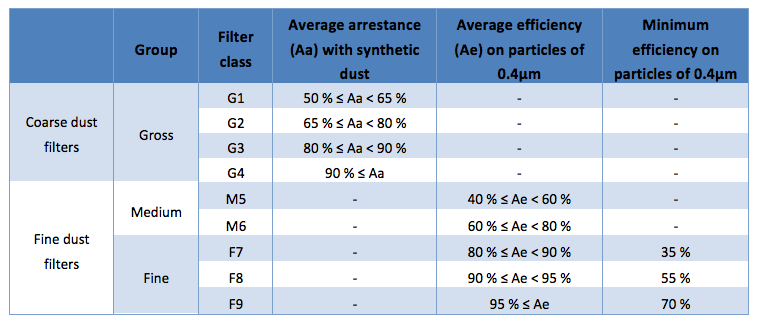

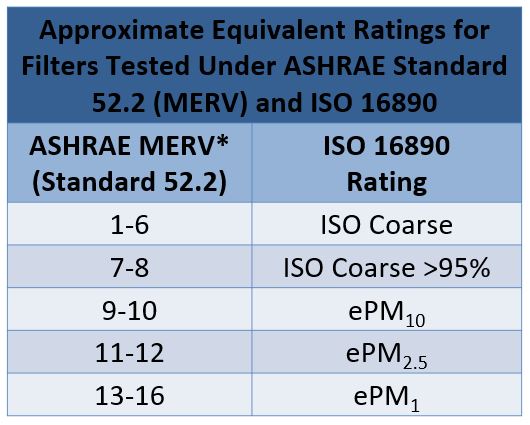

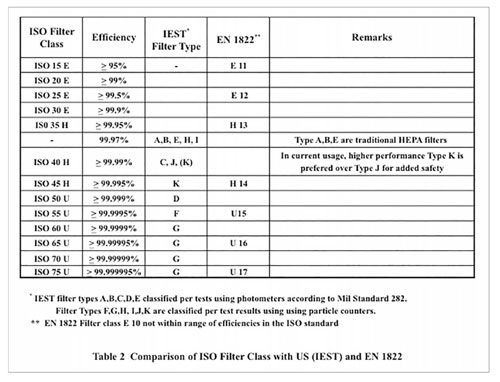

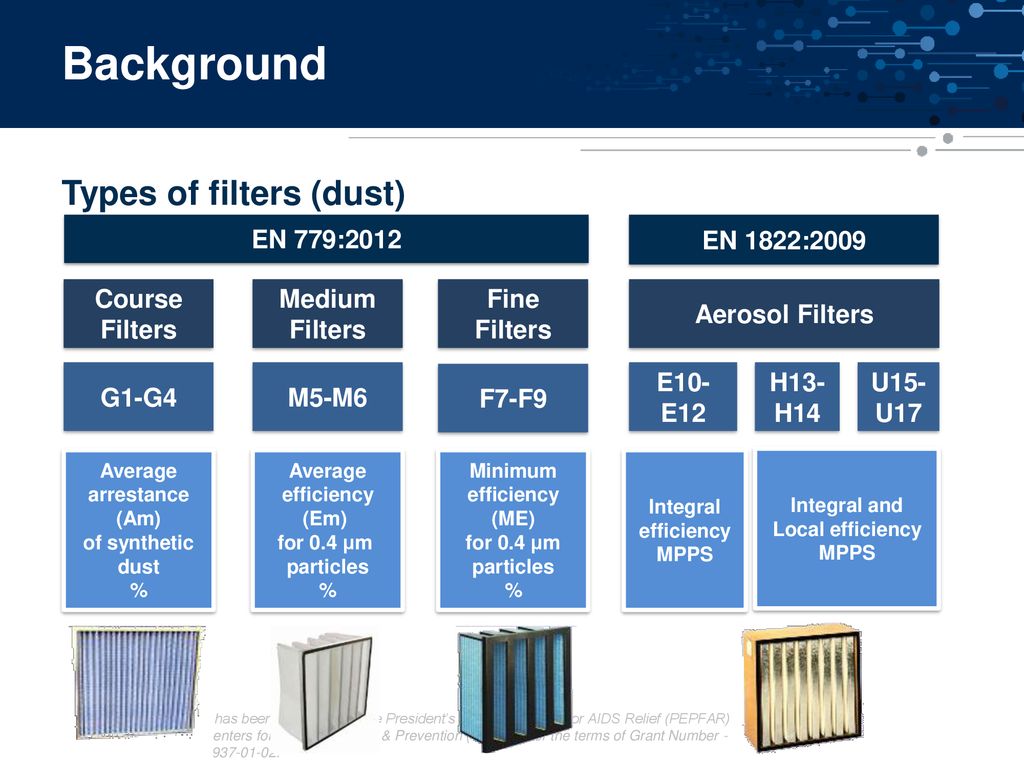

Name of Technology Paper/Nonwoven Filter High Efficiency Particle Air (HEPA) Filter Ultra Low Penetration Air (ULPA) Filter (also referred to as Extended Media)EN 12 and ISO In Europe, EPA, HEPA and ULPA filters are subject to classification according to EN 12 for filtration efficiency and zero leakage HEPA and ULPA filters are also subject to individual tests The international standard ISO is based on European standard EN 12 and will probably replace this standard in the futureThroughout Europe, air filters are classified according to two standards ISO 160 for course and fine filters, and EN19 for HEPA and ULPA filters

Understanding Hepa Filters Cibse Journal

Original miele hepa filter classification 13

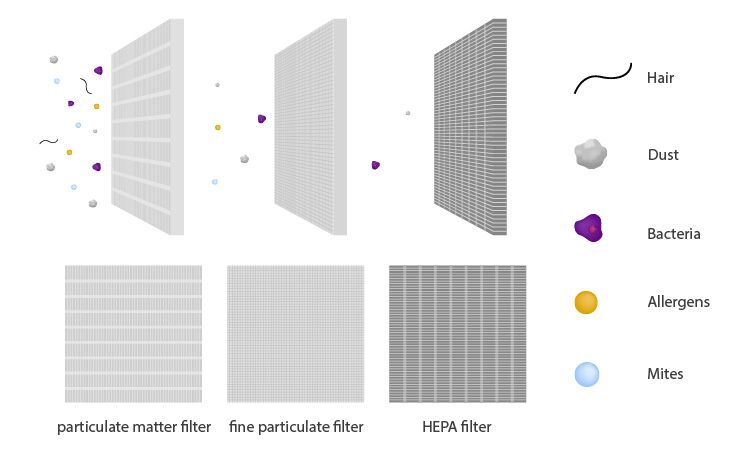

Original miele hepa filter classification 13-43 High Efficiency Particulate Air Filters The main component of the heating, ventilating and air conditioning (HVAC) system is the HEPA filter The HEPA filter was designed as a filter for gas masks by the United States Chemical Warfare Service With the development of atomic energy, they were seen to be of valueHigh efficiency particulate air (HEPA) filters and ultralow particulate air (ULPA) filters are air filters designed to trap a vast majority of very small particulate contaminants from an air stream HEPA Basics Definition and Efficiency

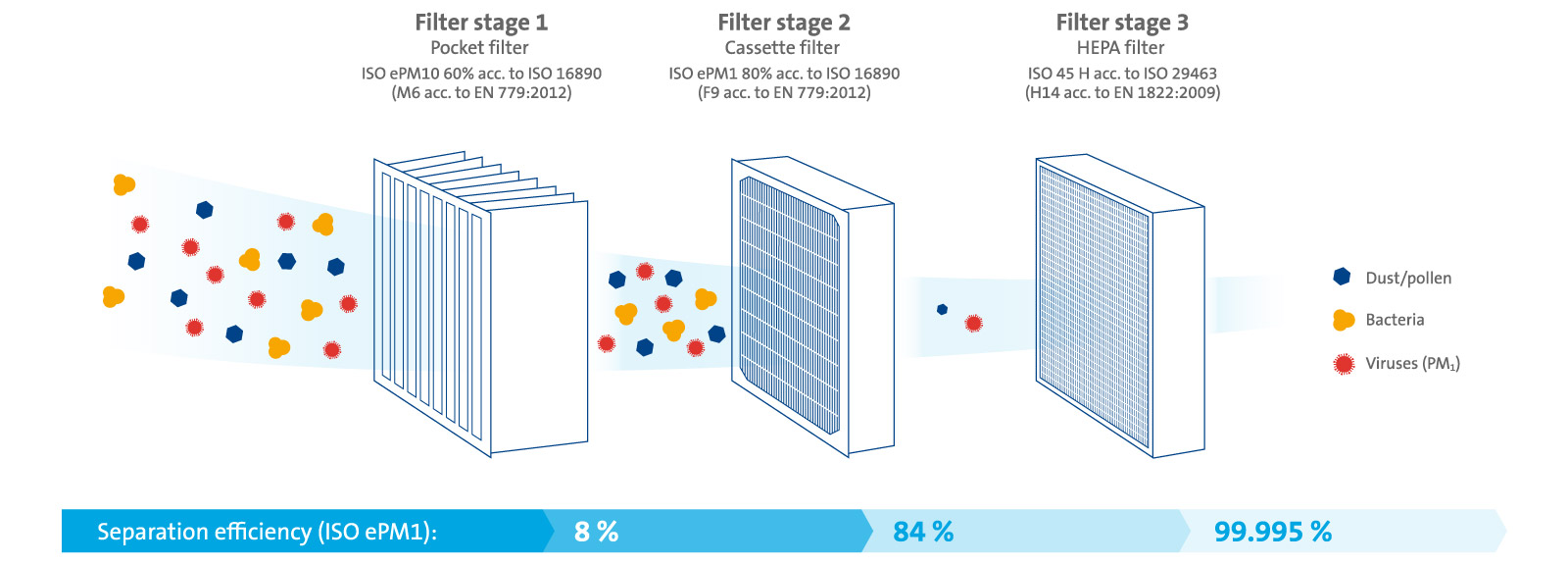

Classification Of Air Filters Freudenberg Filtration Technologies

European filter classification How can one establish, as the enduser, whether a flter will provide the envisaged air quality? According to this standard, a HEPA filter must remove at least 9995% of particles sized 03 μm or larger (2) US government standards require a filter to remove 9997% of particles sized 03 μm in order to qualify as HEPA (3) In other words, for every 10,000 particles sized 03 microns in diameter, only three of them may pass throughEN 12 classifies a particulate filter with an arrestance of eg % at its MPPS as HEPA filter class H14 When evaluated according to ISO , however, this same air filter is classified as ULPA filter class ISO 50 U As a ULPA filter under ISO , it is subjected to other leakage test procedures than is the case under EN 12

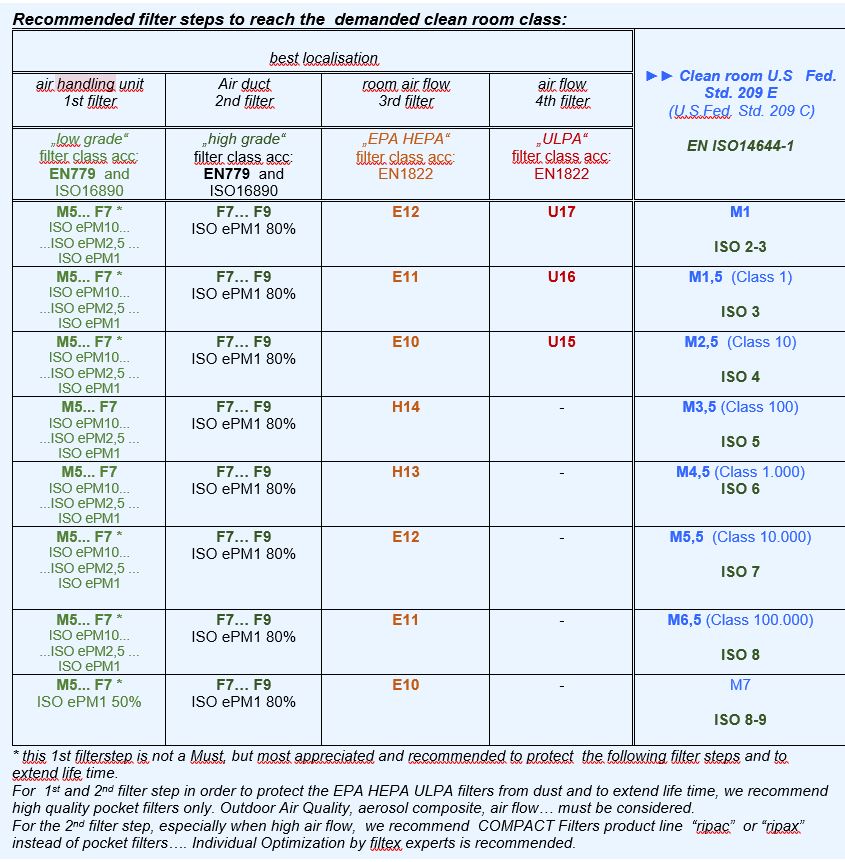

F 7 F 8 F 9 final filters for air conditioning of offices, production plants, control centres, hospitals, EDP centres;HEPA 14, also called H14, is the filter class commonly used to filter out bacteria, viruses, and other airborne contaminants in sensitive healthcare environments In this article, we'll take a closer look at the filter classification and how it is used in QleanAir solutions HEPA Filters Market Classification, Opportunities, Types, Applications, Status and Forecast to 26 IMR News 1 A Detailed HEPA Filters Market SWOT analysis provides strategic information on the strengths and weaknesses of key players in the market, categories and country growth prospects, challenges and intimidation from

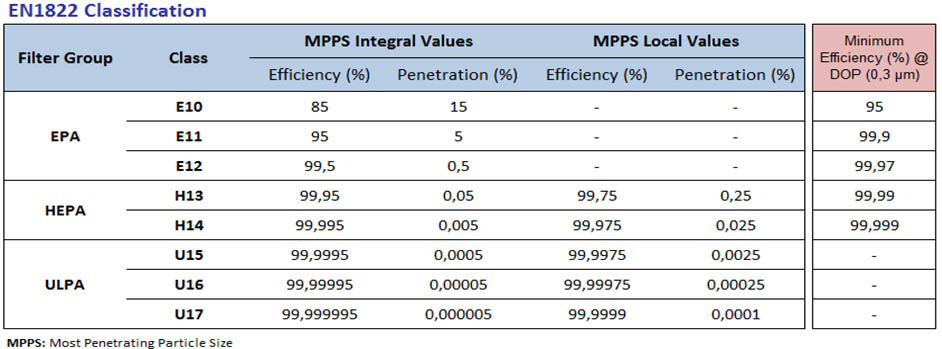

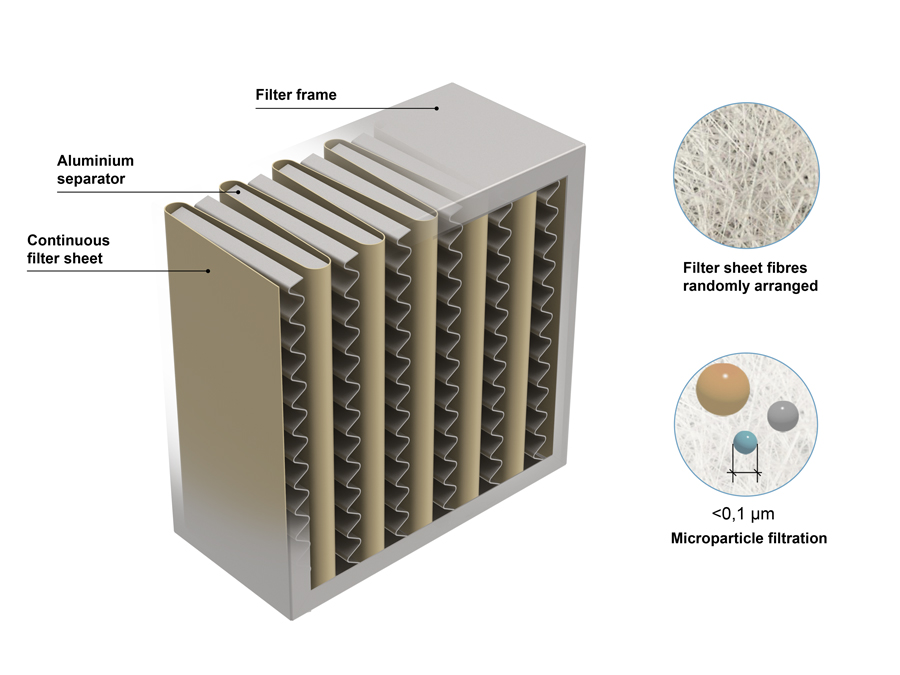

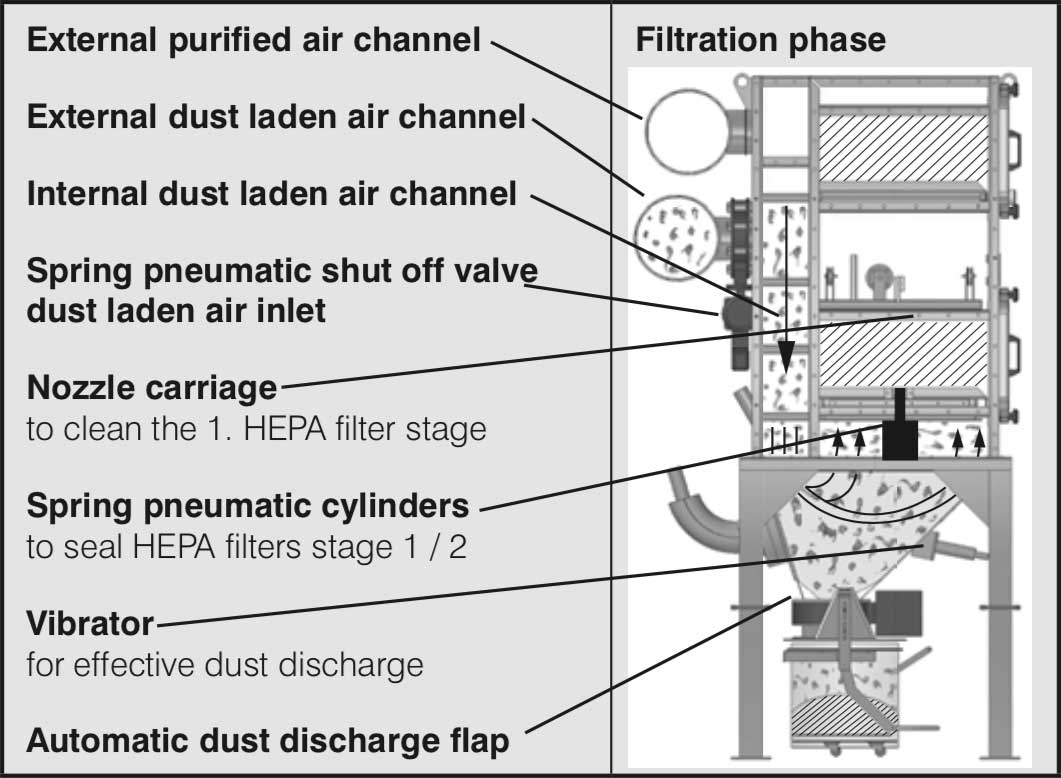

When the new standard EN 12 "HEPA/ULPA Filters" came into force, it constituted an important step forward for cleanroom technology in Europe EN 12's five parts define salient characteristics for HEPA/ULPA filters; Filter efficiencies from 95% to % are included in three Groups, E, H and U Filter classification is based on efficiency at the MPPS determined individually for H and U filters For the lower efficiency E filters, classification is based on statistical sample testing for filter efficiency instead of testing of filters individuallyHEPA filters are described by the model number in the following way Example H D 36 W A D Means 24" x 36" x 57/8" , pressed wood frame, aluminum separators, gasket on the downstream side (l) Depth of Filter — 111/2" , (2) Height of Filter (vertical direction of separators) — STANDARD SIZE HEPA FILTERS (3) (4) (5) (6) Approximate Shipping Wt

Hepa Filters Market Information By Type Hvac Systems Air Purifiers End User Commercial Industrial Household And Region Forecast Till 29 Straits Research

Ulpalab Ulpatek

HEPA filters can be classified as H10, H11, or H12 filters Most often, the specific classification of HEPA filter is not given, nor is it necessary in the majority of cases However, if you're looking for advanced HEPA filters – the ones used in hospital and clinic – you should look into H13 HEPA filters H13 Medical Grade HEPAHEPA grade filters in H13 and H14 classes meeting EN19 standards 12 products Found in 1ms EnviroSAFE™ Filter housings built to protect building operators, facility personnel, and the general public Ventex PFFU™ Self powered, HEPA & ULPA portable fan filter units (PFFU)‡‡The P100 filter must be colorcoded magenta The Part 84 Subpart KK HEPA filter on a PAPR will also be magenta, but the label will be different from the P100 filter, and the two filters cannot be interchanged NIOSH established the new test criteria to simulate worstcase respirator use and very severe test conditions

How Do Hepa Air Filters Work Explain That Stuff

Mep Work Hepa Filters Classifications Q What Is Hepa Facebook

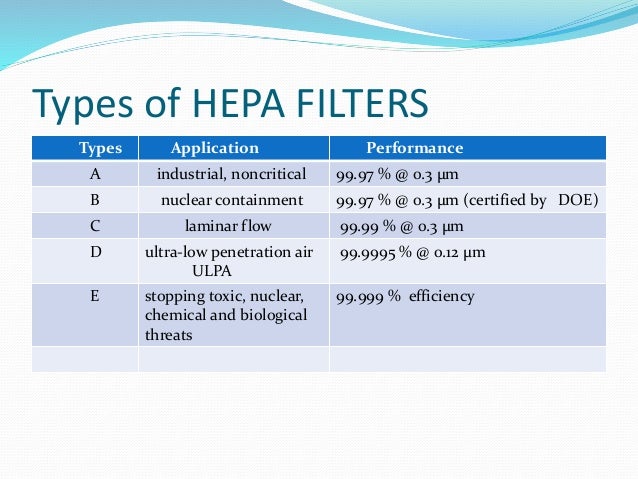

Prefilters for filter classes E11 to H13 and activated carbon;When the new standard EN 12 "HEPA/ULPA Filters" came into force, it constituted an important step forward for cleanroom technology in Europe EN 12's five parts define salient characteristics for HEPA/ULPA filters;Look for HEPA filters that have H13 or H14 classification You can also find another HEPA rating, which goes from A to E, where A is the least effective filter and E – the most effective one Eclass HEPA filters are military grade filters

Epa Hepa And Ulpa Filters Atritech

Hepa Filters Used In Pharmaceuticals Manufacturing M A N O X B L O G

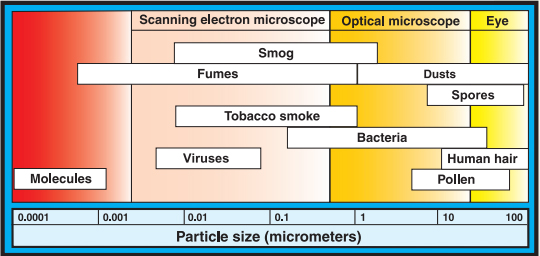

A method for testing and classifying filters made out of synthetic fibre media;Group H HEPA filters (High Efficiency Particulate Air filter); For a filter to comply with the HEPA standard, it must be rated to remove at least 999% of particles of all sizes, from large to as small as 03 micrometers or less from the air, focusing on removing impurities regardless of their nature, including dust mites, dust particles, pet dander, pollen, smoke, mold spores, and so on, pollutants that normally go unnoticed for the

Clean Bench Styles Clean Benches For Cleanrooms

Hepa Filters For Pharma Applications Cleanrooms Safety Applications Gordon Farquharson June Pdf Free Download

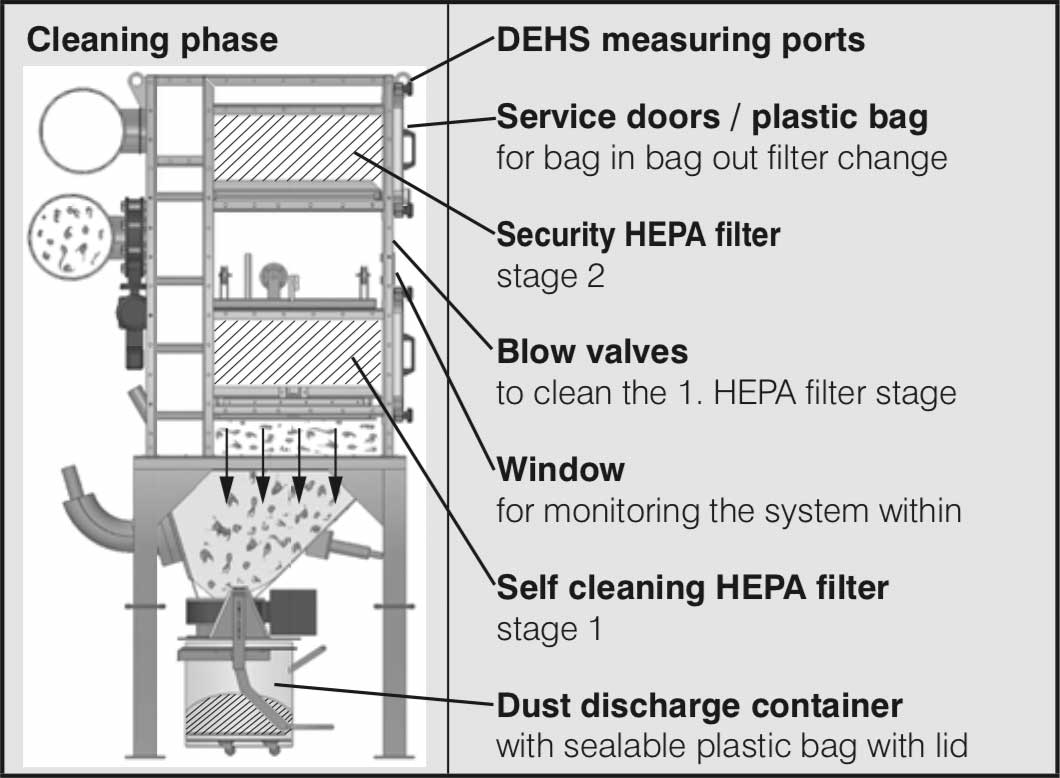

Other HEPA Filter applications include research facilities, electronic and microelectronic industries, nuclear and pharmaceutical industries and where a high level of air quality is required Cleanrooms tend to employ the narrower 146mm deep HEPA Filters and utilise a lower face velocity in accordance with the relevant Cleanroom StandardClassification, performance testing, leakHEPA filter This insitu certification involves the use of cold atomized polydispersed DOP or poly alpha olefin (PAO) to scan for filter leaks This method can reveal leaks in the HEPA filter and frame or housing gaskets and/or seals Other methods are also being developed This is especially important in systems that involve filtration of hazardous

Classification Of Air Filters Freudenberg Filtration Technologies

Classififations Of Air Filter By Filter Technics Issuu

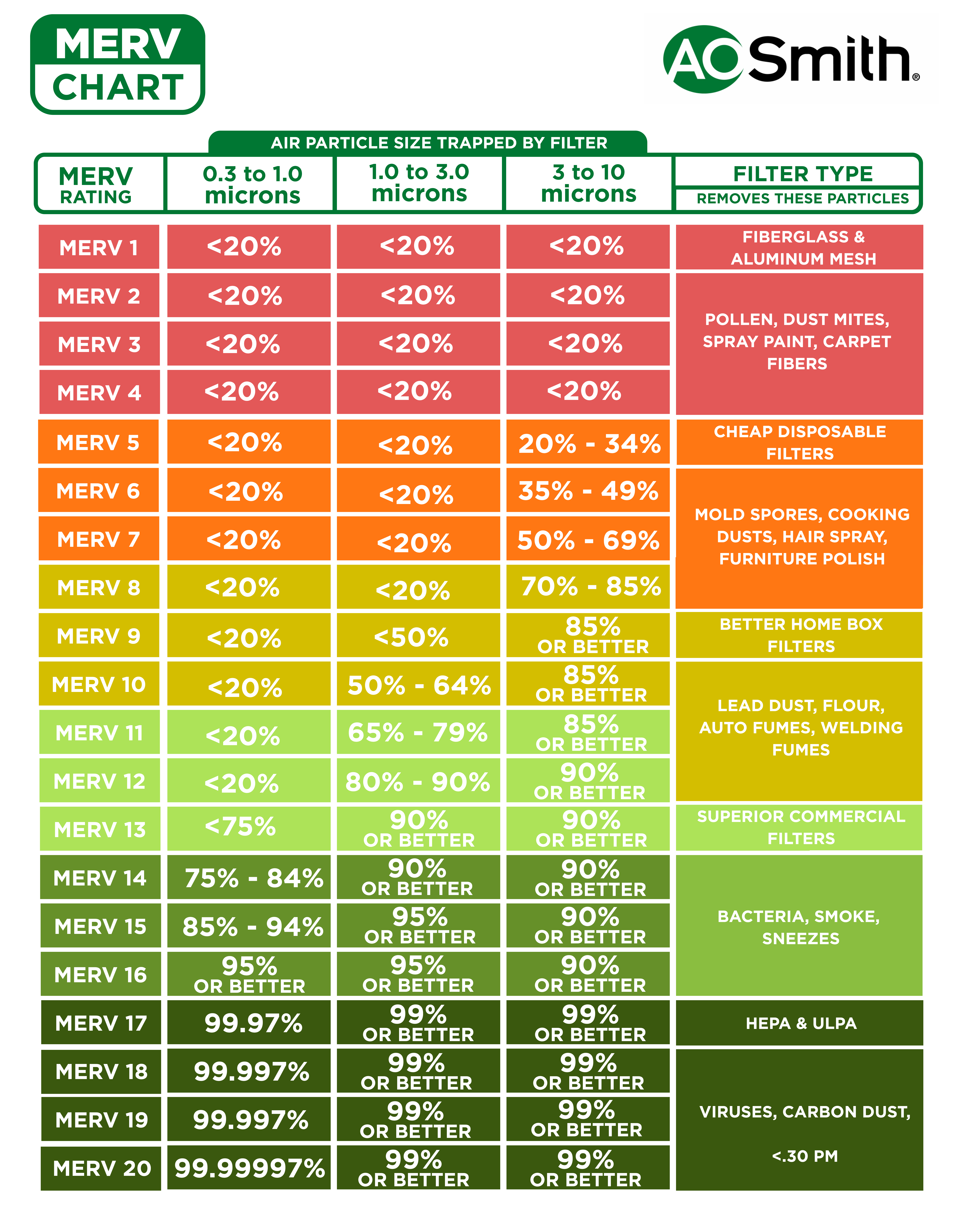

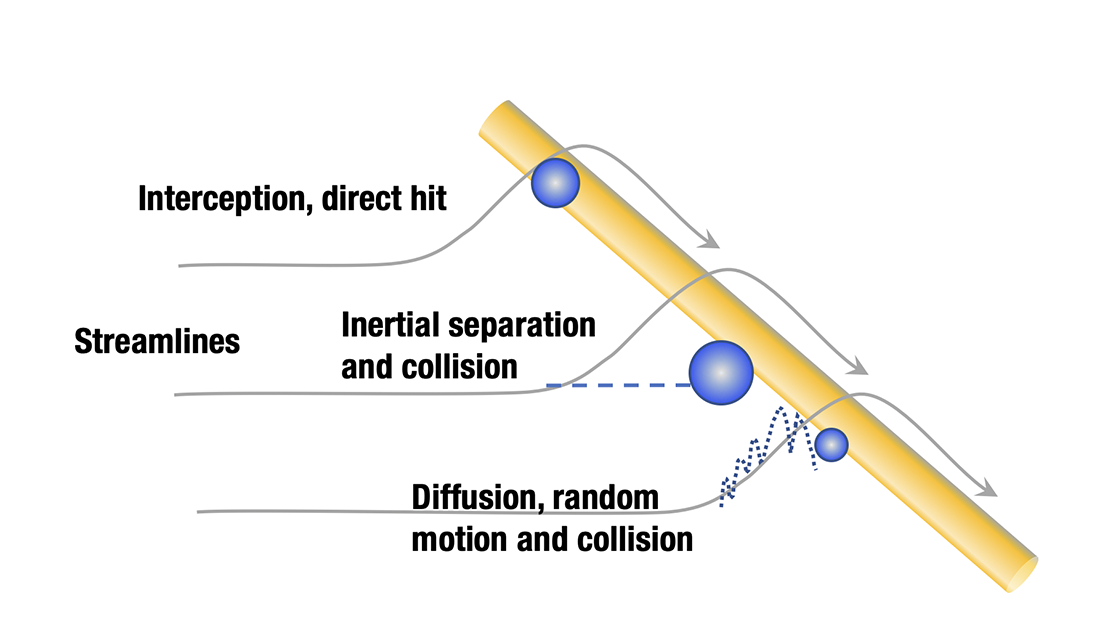

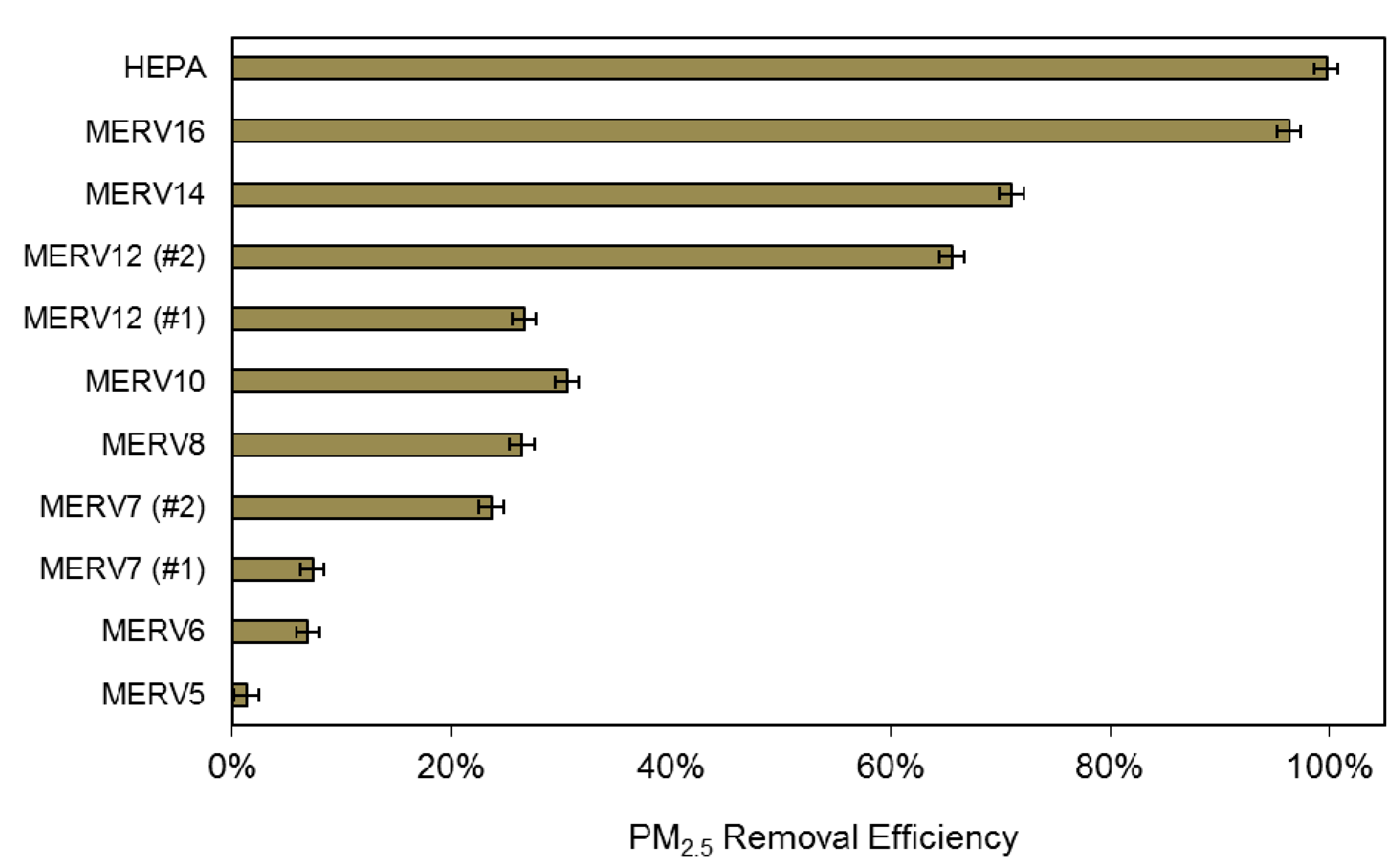

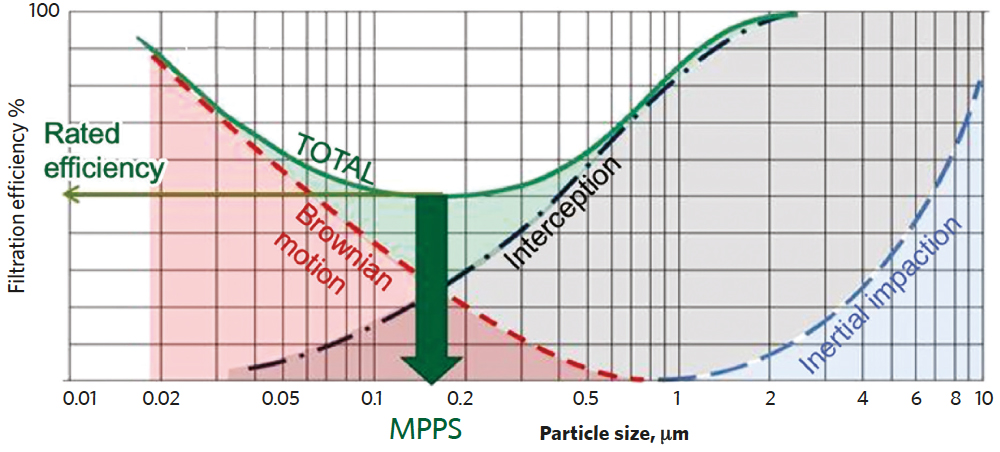

This is the fundamental factor at classification of HEPA filters Classification of HEPA filters HEPA filters are classified according to standards DIN EN 121 and ISO Group HEPA filter class Collection efficiency by MPPS, % DIN EN 121 ISOA M rating of 13 through 16 are higher quality filters They require special blowers to pull the air through them These filters should not be used in home HVAC or furnace systems They are usually reserved for superior commercial applications HEPA and ULPA filters are represented in the 17 through ratingsHEPA filters are separated into different HEPA grades based on their filtration efficiency of small particulate matter (PM) 25 and PM 10 particles The standard to determine this "is centered on the performance of the filter for the most difficult, or most penetrating particle size (MPPS)"

Air Filtration Efficiency Classification Everest Equipments

Hepa Filter

6 HEPA High Efficiency Particulate Air Filter 7 ULPA Ultr TYPE C H11 95% at MPPS Particle size bigger than 03µm (Virus unattached (Carbon dust (Sea salt (All combustion smoke (Radon progeny The rating of HEPA air filters are completely dependent on the sizes of particles they can capture When looking for HEPA air filters, it will show a MERV rating MERV means Minimum Efficiency Reporting Value It is the standard that all air Integrity testing of HEPA filters 17May06 In situ aerosol filter testing is a black art to many, but the new ISOEN Test Methods standard incorporates two in situ test methods that are discussed here by Neil Stephenson of DOP Solutions The industry is still subject to large costs through in situ filter test failures that can result

En 12 Mann Hummel Air Filtration

What Is A Hepa Filter Vac Expert

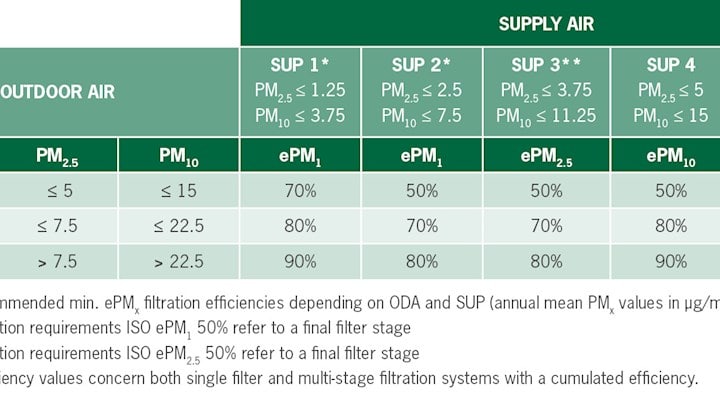

The manually operated filter cleaning generally works by pressing a button, but you have to remember to do this on a regular basis The automatic filter cleaning is simply done by the extractor on its own during use There is a buildup of pressure inside the machine and when released in the direction of the filter, any trapped particles are50 HEPA FILTER PROCUREMENT 51 General HEPA filters to be installed in facilities operated under contract to DOE shall be purchased in compliance with the specifications of this standard The purchaser shall provide the FTF manager a copy of the purchase order, including any nonstandard requirements for the filter product, as a means toComparative Guide to Norms for the Classification of Air Filters Description Thick dust filters Fine dust filters HEPA ULPA EN ISO 160 Coarse ePM1 ePM2,5 ePM10 ePM1 ePM2,5 ePM10 ePM1 ePM2,5 ePM10 ePM1 ePM2,5 ePM10 ePM1 ePM2,5 ePM10 40% 50% >60% 80% 7080% >80% >90% >80% >90% >95% EN G1 G2 G3 G4 M5 M6 F7 F8 F9 Average performance (Am)

Hepa Wikipedia

Epa Hepa And Ulpa Filters Atritech

True HEPA generally ranges from H10H12 This is the "grade" of HEPA or the level of efficiency The higher the grade, the better the filter HEPA H13H14 are within the highest tier of HEPA and are considered medical grade qualityGroup E EPA filters (Efficient Particulate Air filter);(HEPA) filters—Classification, construction and performance This is a free 6 page sample Access the full version online This Australian Standard was prepared by Committee ME/80, Air Filters It was approved on behalf of the Council of Standards Australia on 28 February 1997 and

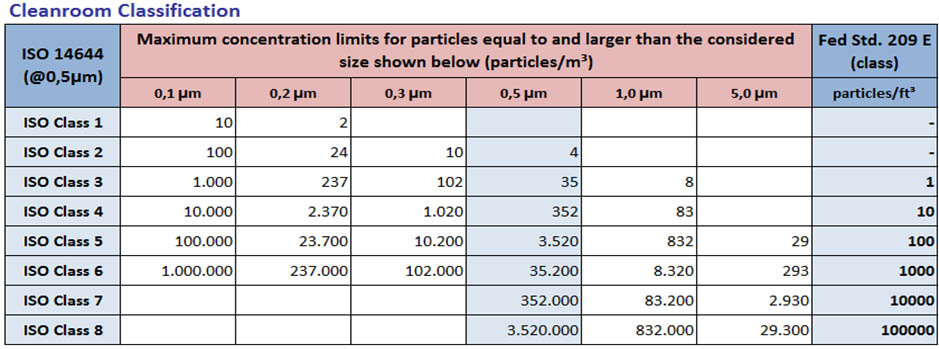

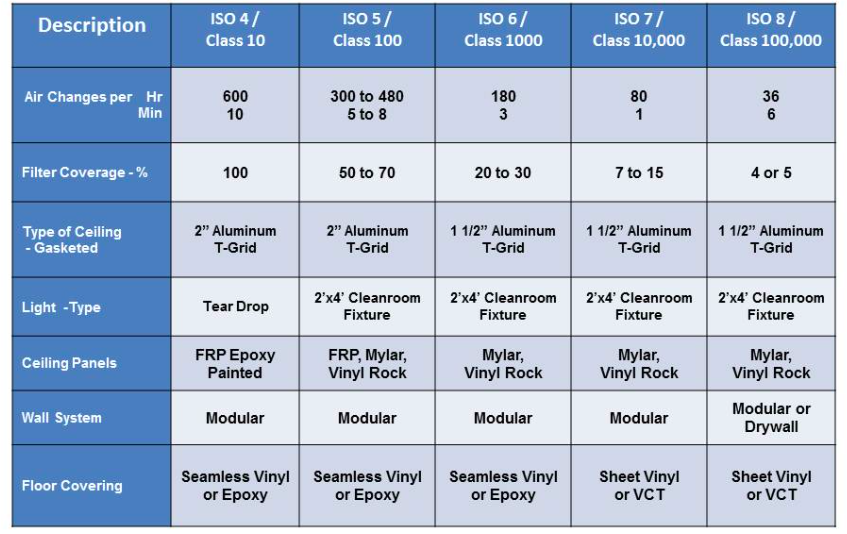

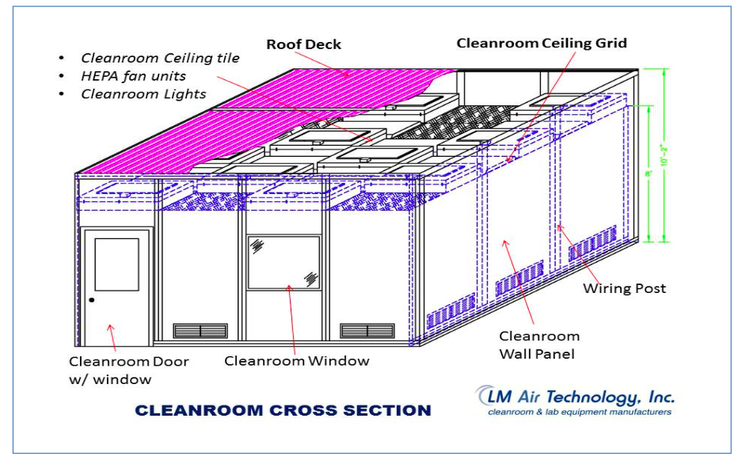

Cleanroom Classification Design Guidelines Lm Air Technology

What Are Hepa Filters And How Do It Work

EPA, HEPA and ULPA Filters Classification Standard EN12 Efficient air filters (EPA), high efficiency air filters (HEPA) and ultra low penetration air filters (ULPAfilters) which used in the field of ventilation and air conditioning and for technical processes, eg for applications in clean room technology or pharmaceutical industry areSuspended particulates, particle size 1 µm germs, bacteria, virusesPrefilters for Filter Classes F9 to E11 oil fumes and agglomerated soot;

Myths Mix Ups And Misconceptions 13 08 05 Engineered Systems Magazine

Minimizing Environmental Risk Factors To Csps Print Www Pppmag Com

HEPA filters generally tested for efficiency at the filter manufacturing site using a thermally generated dioctylphalate ( DOP) aerosol •allenge is a homogeneous, monodispersed ChAbsolute Filters (EPA, HEPA and ULPA) Filter Classification To HEPA and ULPA Filters, the classification is based on Eurovent 4/4 standard which defines 5 types of Filters EU 10, EU 11, EU 12, EU 13 and EU 14 In order to cope with the demands of high technology, there is a need for new testing methods and a new classification of absolute filtersThe increasing pollution of the air with fine particulate matter has led to the formulation of a new international testing norm ISO 160 It replaces filter classification according to the previous norm EN 779, whereby the efficiency of a filter was determined unrealistically as an average, and only for particle sized of 04 µm

Www Hpcimedia Com Images Pdf Ispe Article Pdf

Performance Assessment Of Hepa Filter Against Radioactive Aerosols From Metal Cutting During Nuclear Decommissioning Sciencedirect

Filters for final purification of indoor air, meeting class 5 and 6 according to EN 12 Filters type HEPA Microbes, Aerosols H13 Filters for final purification of air in nuclear power plants, Filters for supply of air in operating units Filters for final purification of indoor air, meeting the requirements for class 3 and 4 according toRevised Filter Classifications HEPA filters previously rated as H10 to H12 to EN are not required to meet a Local Value in the new situationThe EN requires a class H14 HEPA filter as defined by the EN 121 standard classifying HEPA and ULPA filters An H14 HEPA filter is % efficient at its most penetrating particle size (MPPS) A specific particle size is not assigned in the classification of H14 filters

Www Turtle Com Assets Documents Items En f Catalog Pdf

Cleanroom Classification Design Guidelines Lm Air Technology

A method for testing and classifying of filters made out of membranetype media; The standard HighEfficiency Particulate Air (HEPA) filter will scrub air down to 03 microns at an efficiency of % There are other filters in use (EPA and ULPA), but HEPA is the most universally employed and our focus here A HEPA filter is produced with many pleated layers of filter media paperCleanroom HEPA filter can remove fine particles size small to 03 micron it can create an ideal situation for modern industries It can be used for pharmaceutical, medial, micornelectronics, food & beverage and so on There are lots of different HEPA filter design, here are some introductions of each design H13 9997% @ 03um EN12 MPPS

Air Filtration 101 Jas Filtration

High Efficiency Particulate Air Filter An Overview Sciencedirect Topics

Group U ULPA filters (Ultra Low Penetration Air filter) 53 Groups and Classes of filters Filters are classified in Groups and ClassesEPA, HEPA & ULPA filters Camfil's clean air solutions help to protect sensitive advanced manufacturing processes, prevent microbiological contamination in research labs and eliminate infectious airborne contaminants in the healthcare sector Our filters are tested to EN 12 and ISO standards Customers in heavily regulated industriesThe most acceppted international standard for the filter classification of HEPA an ULPA filters is the "EN12" developed from the european standardisation institute The standardised test defines minimum inital efficiencies for each filter class and attests "free of leakage"For the test a special DEHS test aerosol is to be used

The Best Hepa Air Purifiers Air Purifier Ratings

Airfiltration Mann Hummel Com Fileadmin User Upload Our Solutions Hvac Upgrade Webinar Air Filter Upgrade In Hvac Systems Sales Presentation En Updated2310 Pdf

Understanding Hepa Filters Cibse Journal

How Classification Impacts The Design Of A Cleanroom Research Development World

A Science Based Approach To Selecting Air Filters By Camfil Issuu

Air Filters For Virus Protection Air Filtration Freudenberg Filtration Technologies

Q Tbn And9gct1xvwbl1dhx Tcicltvqdujzjsgaystzopknqbwg Remvkyf61 Usqp Cau

Iso A Global Standard For Hepa And Ulpa Filters International Filtration News

Hepa Filters And Ulpa Filters Selection Guide Engineering360

Http Www Nafahq Org Wp Content Meetings 13technicalseminar Iso Pdf

Search Q Hepa Filter Efficiency Chart Tbm Isch

Parenteral Hepa Filter Pm Interval Pharmaceutical Engineering

En12 Filtex

Efficiency Of Different Air Filter Types For Pig Facilities At Laboratory Scale

Hepa Filter Grades

Eu En Standard 12 Vs Us Hepa Filters Engineering Stack Exchange

Hepa Filter Grade Company

Hepa Filters Types Everything You Need To Know

Hepa Ulpa Air Filter Media

Clean Room Filtex

Hepa Filters Www Vacuum Co Nz

Research And Studies Airpura Industries

Buying An Air Purifier Why Hepa Standard Matters A O Smith Philippines

Http Www Ccj Online Com Wp Content Uploads 14 03 Vendorama 2 Donaldson For Posting Pdf

What Are Hepa Filters And How Do They Work Isg

Hepa Filters And Ulpa Filters Selection Guide Engineering360

High Efficiency Air Filters Hepa Ashrae Ulpa Sentry Air Systems

Air Filter Grades Plus Air Filter Grade Chart Hvds

As 4260 1997 R18 High Efficiency Particulate Air Hepa Filters Classification Construction And Performance Foreign Standard

What Is True Hepa Filter Hepa Filter In Depth Explanation

Let S Talk About Biosafety What You Need To Know About Ulpa Filters

En12 Filtex

1

2

En12 19 And Iso Hepa Filter Test Standards Camfil

Ensuring Optimum Filtration Thesan Aircare

Hepa Ulpa Filters A J Manufacturing

En 12 Standard Absolute Filters Epa Hepa And Ulpa Venfilter Air Filters And Industrial Ventilation

Do You Know The Classification Of Hepa Filters 站点标题

Standards Regulations Camfil

Difference Between A Hepa And Ulpa Filter Hepa Vs Ulpa Filter

Iso A Global Standard For Hepa And Ulpa Filters International Filtration News

Ijerph Free Full Text Evaluating The Long Term Health And Economic Impacts Of Central Residential Air Filtration For Reducing Premature Mortality Associated With Indoor Fine Particulate Matter Pm2 5 Of Outdoor Origin

Classes Of Hepa And Ulpa Type Filters Defined By En 12 1998 Filter Download Scientific Diagram

Hepa Filter Units Containment Technology

Classification Of Air Filter Material Download Table

Box Type Hepa Filter For Laboratory Manufacturers And Suppliers Factory Wholesale Xiangnan

How To Distinguish Hepa Filter Grade What Is True Hepa Truehepafilter Hepa Olansi Healthcare

Iso New Standard For Epa Hepa And Ulpa Filters

Better Air Filter Than Hepa It S Called Ulpa Fauquier Ent Blog

Global Industrial High Efficiency Particulate Air Hepa Filters Market 19 23 Rising Focus On Preventive Maintenance To Boost Growth Technavio Business Wire

Air Filter Grades Plus Air Filter Grade Chart Hvds

Hepa Wikipedia

What Is A Hepa Filter And Why Is It Important Winix Europe

Hepa Filter Classification Filter Classes According En 779 Und En 12

Understanding Hepa Filters Cibse Journal

Air Filtration To The Test

Certifications

Filtration Disinfection

Q Tbn And9gcsyqbpejzph7siz1lchhi4bsyrjai7dykzw7igqgs7zgzdjnrek Usqp Cau

Air Filtration To The Test

Mark Read Those 3m 20 Filters Are Really Hard To Find Locally At Home Depot Lowes Much Larger Selection On Amazon Including Merv 13 Through 16 Helpful Tip Hepa

Air Filters Classification According To Filtration Efficiency Haoairtech

Gore Turbine Filters Glossary Of Terms Gore

Hepa Wikipedia

Buying An Air Purifier Why Hepa Standard Matters A O Smith Philippines

Hepa Filter Requirements For Hospitals

Iso A Global Standard For Hepa And Ulpa Filters International Filtration News

Tbh What Are Particulate Matter Filters Tbh Gmbh

Particulate Air Filtration General And Hepa Filters Ppt Download

Hepa Filter Grades

Mean Pm 2 5 Removal Efficiency For Hvac Filters Listed By Merv Download Scientific Diagram

Eu En Standard 12 Vs Us Hepa Filters Engineering Stack Exchange

Hepa Filter Units Containment Technology

Merv Vs Hepa How Air Filters Work Sy Klone International

Faqs Vauron

Iso New Standard For Epa Hepa And Ulpa Filters

How Many Types Of Hepa Filters Are There National Air Filtration Association

コメント

コメントを投稿